The Future of Stainless Steel Industry: Trends, Challenges, and Opportunities

2025-03-06 14:08The Future of Stainless Steel Industry: Trends, Challenges, and Opportunities

The stainless steel industry is undergoing a significant transformation, driven by technological advancements, evolving market demands, and sustainability initiatives. As one of the most versatile and widely used materials, stainless steel continues to play a critical role in various sectors, including construction, automotive, healthcare, and consumer goods. This article explores the latest trends, challenges, and opportunities shaping the future of the stainless steel industry.

1. Growing Demand for Stainless Steel

The global stainless steel market is projected to reach $182.3 billion by 2030, growing at a CAGR of 6.3% from 2023 to 2030. This growth is fueled by increasing demand from emerging economies, urbanization, and infrastructure development.

Construction Sector: Stainless steel is widely used in building facades, roofing, and structural components due to its durability, corrosion resistance, and aesthetic appeal.

Automotive Industry: The shift towards electric vehicles (EVs) has increased the demand for lightweight, high-strength stainless steel components.

Healthcare Applications: Stainless steel's hygienic properties make it ideal for medical devices, surgical instruments, and hospital equipment.

2. Technological Advancements in Stainless Steel Production

Innovations in manufacturing processes are revolutionizing the stainless steel industry, improving efficiency, quality, and sustainability.

Smart Manufacturing: The integration of IoT (Internet of Things) and AI (Artificial Intelligence) in stainless steel production enables real-time monitoring, predictive maintenance, and optimized resource utilization.

Additive Manufacturing: 3D printing technology is being used to create complex stainless steel components with reduced material waste.

Advanced Coatings: New coating technologies enhance the corrosion resistance and lifespan of stainless steel products, expanding their applications in harsh environments.

3. Sustainability and Circular Economy

Sustainability is a key focus for the stainless steel industry, with companies adopting eco-friendly practices to reduce their environmental footprint.

Recycling: Stainless steel is 100% recyclable, and the industry is increasingly using recycled scrap metal to produce new products. This reduces the need for raw materials and minimizes waste.

Energy Efficiency: Manufacturers are investing in energy-efficient technologies, such as electric arc furnaces (EAFs), to lower carbon emissions.

Green Certifications: Companies are obtaining certifications like ISO 14001 to demonstrate their commitment to environmental sustainability.

4. Challenges Facing the Stainless Steel Industry

Despite its growth prospects, the stainless steel industry faces several challenges that need to be addressed.

Raw Material Costs: Fluctuating prices of nickel, chromium, and other raw materials impact production costs and profit margins.

Trade Barriers: Tariffs and trade restrictions in key markets, such as the US and EU, create uncertainties for global stainless steel suppliers.

Competition from Alternatives: Materials like aluminum and carbon fiber are gaining traction in certain applications, posing a threat to stainless steel's market share.

5. Opportunities for Growth

The stainless steel industry is poised for growth, with several opportunities on the horizon.

Emerging Markets: Rapid industrialization in countries like India, Brazil, and Southeast Asia is driving demand for stainless steel in infrastructure and manufacturing.

Innovative Applications: The development of new stainless steel grades, such as duplex and super duplex stainless steel, is expanding its use in extreme conditions, including offshore oil rigs and chemical plants.

Collaborations and Partnerships: Companies are forming strategic alliances to leverage each other's strengths and explore new markets.

6. Spotlight on Foshan Gaoming Ouyigang CNC Machinery Co., Ltd.

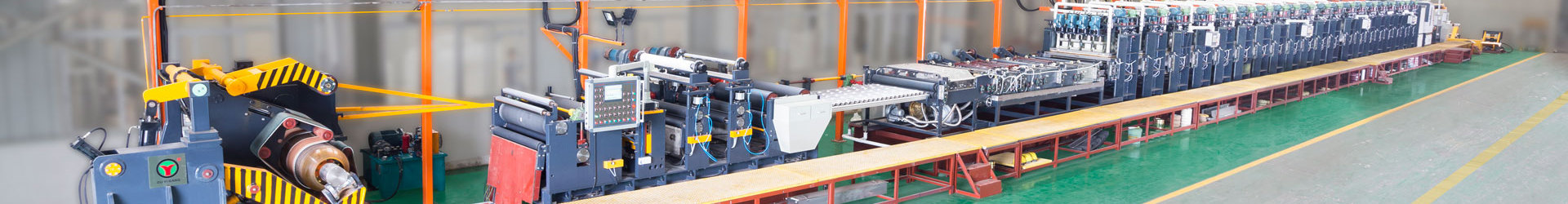

As a leading player in the stainless steel processing industry, Foshan Gaoming Ouyigang CNC Machinery Co., Ltd. is at the forefront of innovation. The company specializes in advanced CNC equipment, including 8K polishing machines, which deliver mirror-like finishes for stainless steel surfaces.

Product Excellence: Ouyigang's 8K polishing machines are renowned for their precision, efficiency, and durability, making them ideal for industries like appliances, kitchenware, and decoration.

Sustainability Commitment: The company is committed to eco-friendly manufacturing practices, reducing energy consumption and waste in its production processes.

Global Reach: With a strong presence in international markets, Ouyigang is helping customers worldwide achieve superior stainless steel finishes.

7. Conclusion

The stainless steel industry is at a pivotal moment, with immense potential for growth and innovation. By embracing technological advancements, sustainability initiatives, and strategic collaborations, companies can overcome challenges and seize new opportunities. As a trusted partner in the industry, Foshan Gaoming Ouyigang CNC Machinery Co., Ltd. continues to lead the way with cutting-edge solutions and a commitment to excellence.