Grinding Machine For Stainless Steel Coil

The synchronization of the whole line is stable, the operation is simple, the board input and output are fast, efficient, and the response speed is fast, and the emergency stop automatically protects the board surface.

The area of the whole line is reasonably designed, the basic engineering is simple and practical, the engineering cost is reduced, the site layout is convenient for operators to control, and the production is safe.

High automation, only need two operators, high efficiency.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

Grinding Machine For Stainless Steel Coil

Product Description

As the name suggests, it is the evolution of the company's 20-years long experience.

During processing the sheet and coil, the grinding liquid is oil and water mixed together.

The whole of the water inquiry is based on the parameter of the grinding head and the other parameter of the assemble machine in production line.

The grinding roller's diameter is Φ350 with the non-woven fiber, during the grinding 8K, it can removed the oxidized part with coarsed grinding and hailine effect.

With 15KW motor and V-Belts, it can control the speed frequencyly by the 15 KW motor and the V-Belt.

Other parameter

| Usage | It process the surface with hairline craft on working plate |

| The plate thickness | 0.4-3.0 mm |

| Transmit inspect | The transmit was moved by the turbo vortex |

| The grinding head | 1 or 2, 3 sanding heads |

| Processing of plate width | 820-1550 mm |

| Processing speed | ≈20 m/min |

| Weight | 6.5 ton/ group |

| Grinding roller | 1 Sets |

| Material of the transmit roller | Cover with the Bubber |

| The diameter of the transmit roller | 150 mm |

| The motor of the transmit system | 15KW |

| Total power unit | 12-16KW |

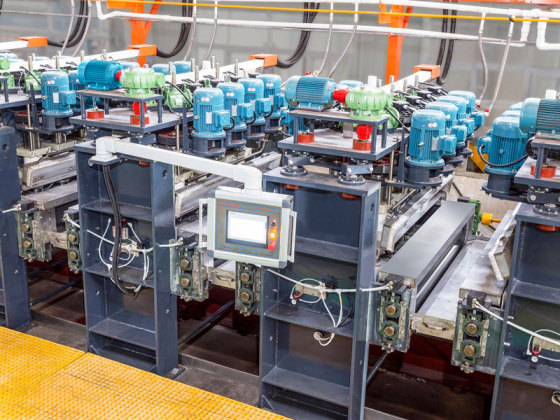

Details of machine

1. The hairline machine could manufacture by customized.

2. The eccentric shaft was controled by the 15 KW motor, and followed by the V-Belt and the speed is frequency.

3. The maximun eccentric range is up to 20 mm.

4. The worm-gear case lift synchronously with the regulation of the electric lift.

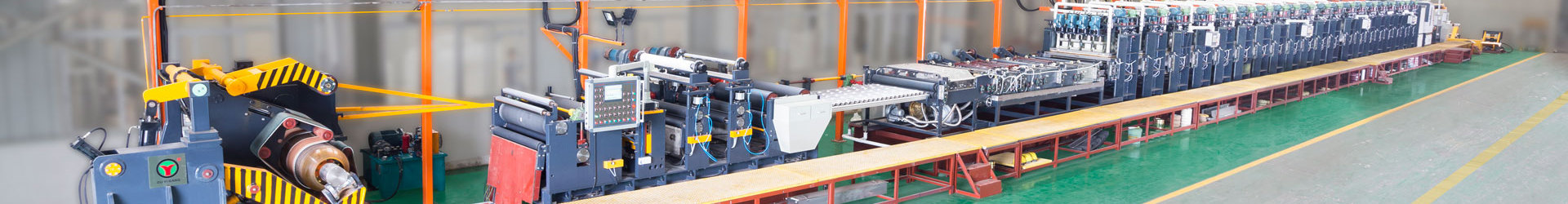

Production line

It includes:

A. Transfer rack

B. Decoiler

C. Pinch and levelling unit

D. Main machine for polishing, hairline machine

E. Cleaning & drying machine

F. Tension unitfilm lamination machine

G. Coiler

H. Filtering system

I. Other necessary equipments.

As above, it is the basic production line, in order to keep the stainless steel raw coil feed into the finished coil, we have the automatic feed machine, like the decoiler, release the coil to through the Pinch and levelling unit, then it come into the pinch levelling unit, make the coil surface would not change, cut down the delimotion of the working plate, during the main machine working, worker control the speed of the line under the situation of the coil surface and the requirement of the sanding.

Our Services

After-sale service: We supply technique service to our customer over sea for one month.

Pratice: We practise the user about the operation and maintaince, the transfer.

The transfer part of the broken: Please feel free to contact us, and do not transfer the broken part by yourself until our indicating.

FAQ

1. What is the usage of the machine?

It usd to processing the surface of the stainless steel with the sanding craft.

2. What is the latest shipping date of the production line?

It need 45 days to manufacture the whole production line.

3. Are you a factory or trading company?

Factory. Specializing in manufacturing and designing by customer.

4. What is the packing and shipping?

It will di-assemble the assemble machine, then we will pack the part in the wooden box or it will cover the apperance with the transpart plastic film, then the whole machine will be put into the 40 HQ.

Contact us

Tel:86-757-88627213

Fax: 86-757-88627213

Mobile phone:+86-13425703089

Address detail :No.19,Xingliang Road, Sanzhou Town, Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

City: FoShan

Province:GuangDong

Country:China