Stainless Steel No.4 Surface Grinding Machine

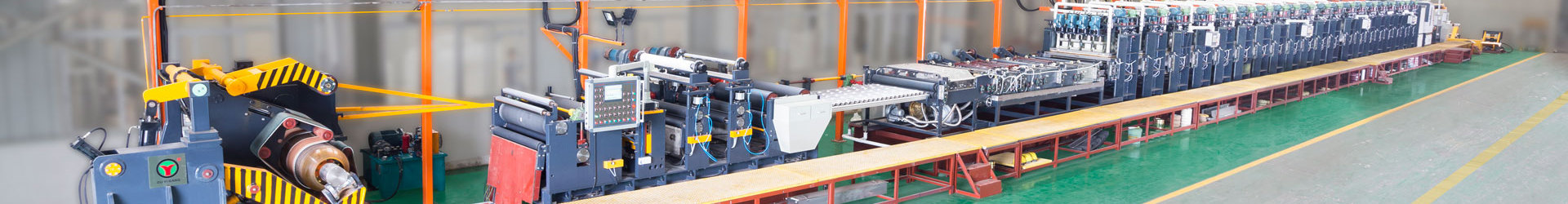

Combining foreign advanced design concepts and cutting-edge technology, using Siemens functions to develop a patented CNC operating system, it is the future trend of metal surface processing equipment, with automation, high efficiency, energy saving, safety, stability and other characteristics.

After years of research and development, combined with the actual use of a number of patented technologies of our company, it has the characteristics of automation, high efficiency, energy saving, safety and stability.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

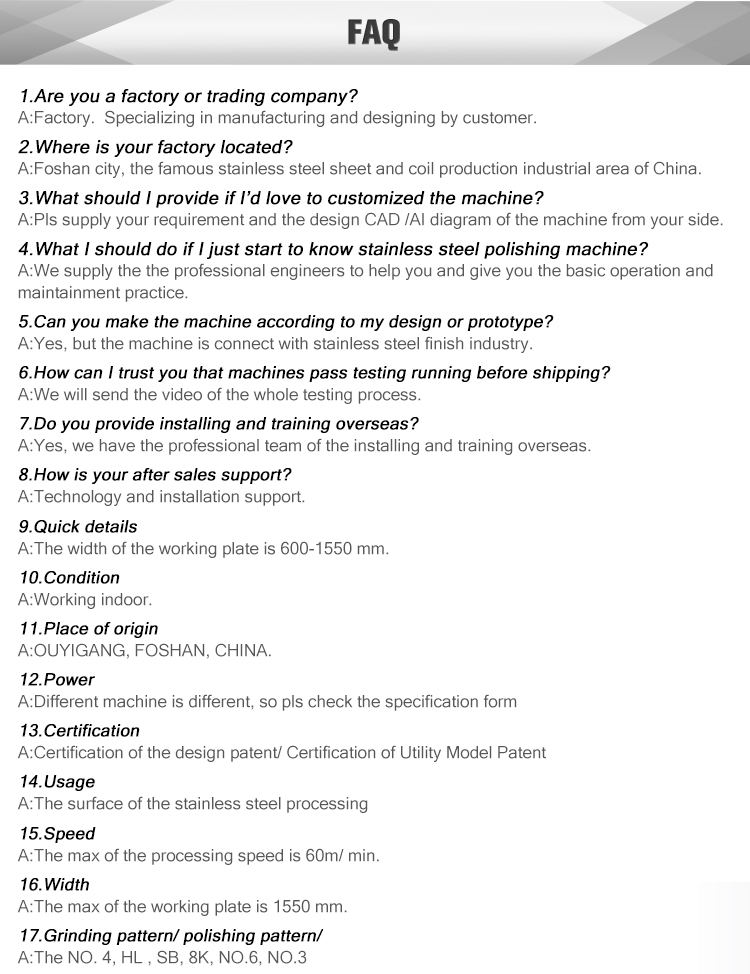

Stainless Steel No.4 Surface Grinding Machine

(with No.4,Hairline,SB finish)

Performance and the characteristic

human oriented design,energy-save and environmental, easy to clean and maintained

Operated conveniently and easily, controlled with CNC system.

Use kinds of patents, such as grinding head, Variable frequency speed regulation, high efficient, scientific structure grinding steadily when it work

Transmit steadily, the whole production line realize highly synchronous, converter technique ,servo technique, speed adjusting make the production have high efficient and steady quality.

It use high technology, such as photoelectric detection with high degree or accuracy, intelligent adjusting, making the best swing evenly during the production and realize the effect of general protection.

This production line all use mixed water-oil mixture, it is economy , environmental and safety and making the product have bright color.

Most of the inside structure itself is made of stainless steel .

Company Advantage

1. Original and unique design

OUYIGANG Machinery have unique and advanced machine design. It is matching on good material and high-configuration design: Safe, quick, practical and etc that different style for steel processing, welcome to contact us for more information about new design.

2. High & stable quality

OUYIGANG Machinery is from material purchasing, and the whole producing, we guarantee customers “high quality, stable quality”. Our products had passed CE certification, ISO9001-2008, ISO14001 and other quality test report. third part inspection is available whenever it is requested.

3. Well material

OUYIGANG Machinery are produced with well material by high technology, environmental, long service life and safe. It will always create to you a comfortable and reassured work life.

Cooperation company

Why choose us

Excellent quality from material to processing

OUYIGANG is technologically advanced machinery that compared to other alternative products, strictly quality controllers and strongly supervises the quality from material purchasing, compare, test and then decide the original material which is satisfied customer request. During the producing, we must be following closely to make sure the quality is excellent and is same as our confirmed sample. OUYIGANG can be supplied in sheet to sheet ,coil to coil and even cut to length ,for this last option, OUYIGANG has PUR technology in order to offer its product the finish according to its quality.

Basic specification for the machine:

Belt abrasive station | No.4 | / | Hairline |

Brush abrasive station | / | SB | / |

System | Wet roller grinding | Wet roller brushing | Wet roller grinding |

No. of working unit | 2-3 grinding heads | 2-4 polishing heads | 2-3 grinding heads |

Machine weight | Appro 13T | 11T | 13T |

Working width | 900,1250,1500mm, , customized available | ||

Sheet size | 1250X2500mm 1550X3000mm customized available | ||

Sheet thickness min / max | 0.3-4mm | 0.3-4mm | 0.3-4mm |

Roller dimensions(Od X width) | 300mm | 350mm | 250mm |

Abrasive belt width | Depending on the sheet width | ||

Abrasive belt length | 2620mm | / | 2620mm |

Speed of the line | 6-25M/min | 6-25M/min | 6-25M/min |

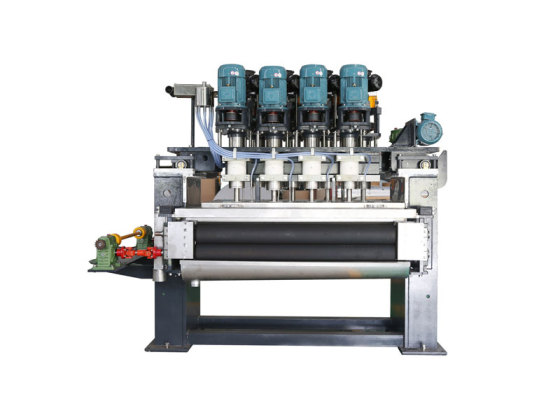

Component parts

1.Unwinding Machine

2.Pinch Leveling Cutting

3.Paper Collecting Unit

4.Auto Feeding Table

5.Bottom side NO.4 Polishing Machine

6.NO.4 Polishing Machine

7.Hairling Machine

8.Cleaning and Drying Machine

9.Fully Auto Laminator

10.Auto Unloading Table

11.Tension Device (Including CPC)

12.Recoiler