Daily use and maintenance of stainless steel oil No.4 sanding machine

2023-07-15 15:00Daily use and maintenance of stainless steel oil No.4 sanding machine

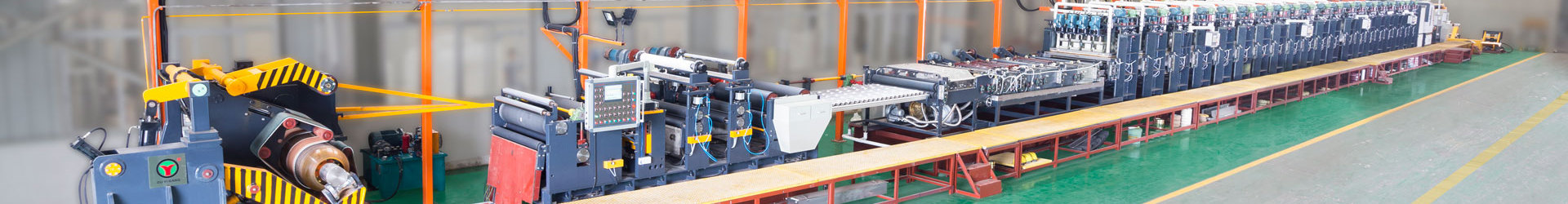

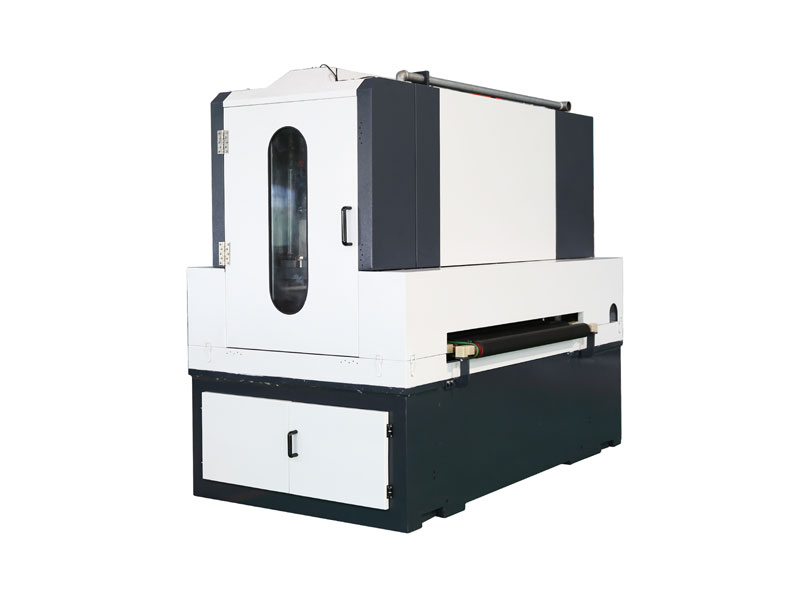

Stainless steel oil No.4 sanding machine is a commonly used mechanical equipment for sanding the surface of stainless steel to make the surface smooth and uniform. Proper use and maintenance can not only prolong the service life of the oil sanding machine, but also improve work efficiency and product quality. Here are some suggestions for the daily use and maintenance of Stainless steel oil No.4 sanding machine.

First of all, before using the stainless steel oil sanding machine, it is necessary to conduct a comprehensive inspection of the machine to ensure that all parts are in good working condition and there is no loose or damaged place. At the same time, check whether the power cord of the Stainless steel oil No.4 sanding machine is normal, and whether the grinding wheel and belt are installed correctly.

When performing sanding operations, you first need to choose a suitable grinding wheel or belt, and choose a different thickness of grinding wheel or belt according to your needs. At the same time, it must be replaced in time according to the degree of wear of the grinding wheel or abrasive belt to ensure its working effect. When working, pay attention to maintaining a stable working angle and speed, and avoid excessive force or pushing the oil sander too quickly.

During use, keep the machine clean and dry. Clean up the dust and dirt on the surface of the machine in time to avoid affecting the normal operation of the machine. At the same time, it is necessary to regularly clean the oil and metal chips inside the oil sanding machine to maintain the working effect of the machine. During the cleaning process, pay attention to the use of professional cleaning agents and follow the relevant safety operating regulations.

In addition, pay attention to safe operation. When using a Stainless steel oil No.4 sanding machine, wear protective glasses and a mask to prevent sand and dust from harming the eyes and respiratory system. Also, make sure the work area is well ventilated to keep the air fresh. When you stop using it, turn off the power in time and unplug it to avoid accidents.

Finally, regular maintenance of the machine is also very important. Regularly replace the lubricating oil inside the machine, and keep the lubricating oil sufficient. At the same time, it is also necessary to regularly check whether the wires and plugs of the machine are damaged, and repair or replace them in time. Regularly check whether the motor and transmission of the machine are normal to ensure the normal operation of the machine.

In short, the correct use and maintenance of Stainless steel oil No.4 sanding machine can improve its work efficiency and service life, and ensure product quality and work safety. Through regular inspection and maintenance, problems can be found and solved in time to avoid machine failure. Only by doing a good job in daily use and maintenance can the role of the Stainless steel oil No.4 sanding machine be fully utilized.

Contact:

David Qiu(Manager) :

Whatsapp : +86 13425703089

EMAIL: manager@ouyigang.com

Crystal Huang :

Whatsapp : +86 13202911839

EMAIL: crystalhuang@ouyigang.com