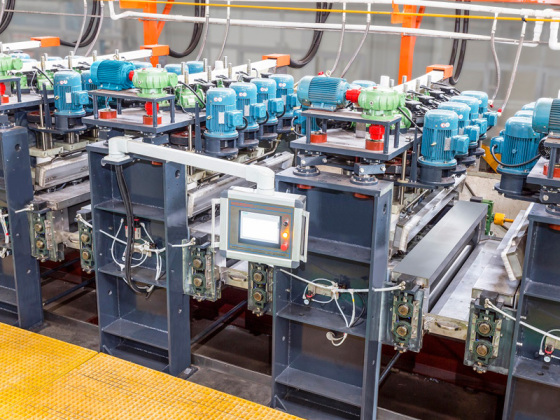

NO.8 Buffing machine for Stainless Steel Sheet

1. Energy saving and environmental protection.

2. Each part of the equipment is made of special materials to reduce the corrosion of polishing fluid.

3. High automation, high working efficiency, simple operation, reduce unnecessary manual operation

4. Easy to replace polishing grinding head.

5. Easy maintenanc.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

Stainless steel sheet NO.8 buffing machine

Main Parameters

Work Pieces: Stainless Steel Sheets of all grades

Useful thickness: 0.6~~3 MM

Useful Width: 1,250 MM(Max) or 1,550 MM(Max)

Processing Speed: 0.5~~1.2 M /Min

Features of No.8 Buffing machine

1. Energy saving and environmental protection, with environmental protection system, special treatment for waste liquid, recycling.

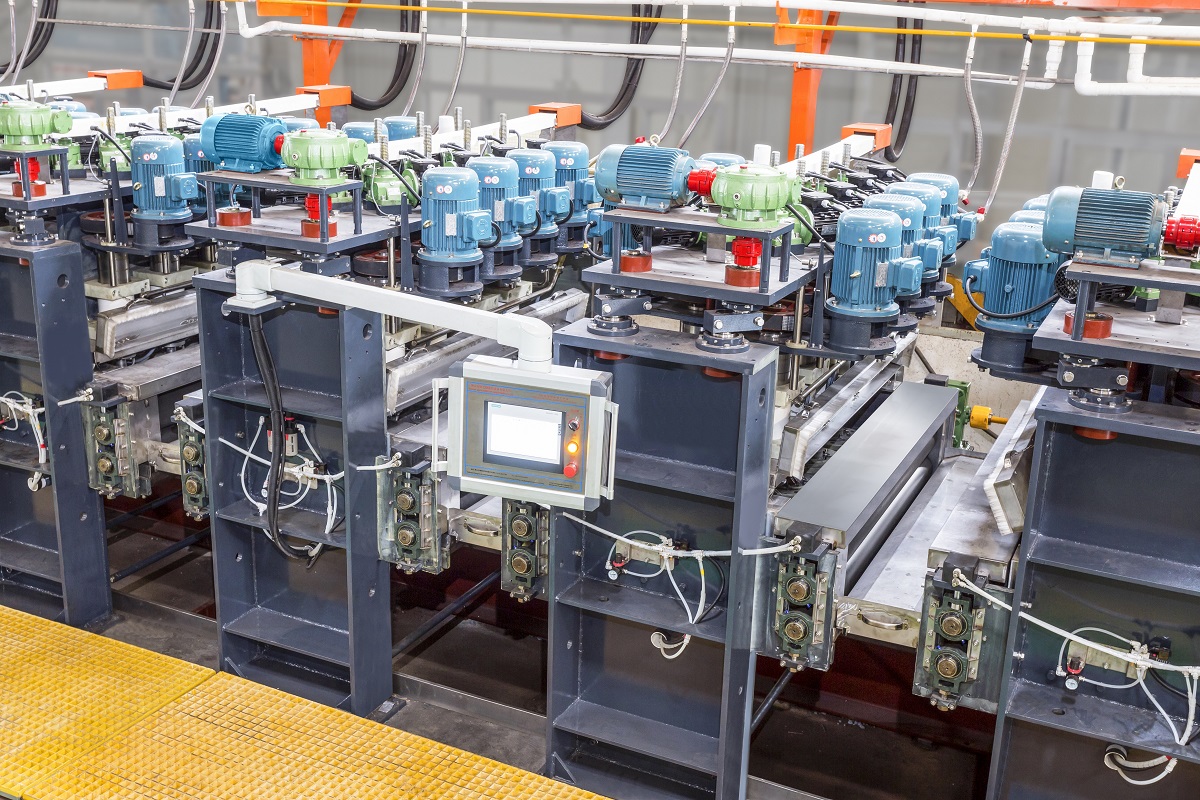

2. Each part of the equipment is made of special materials to reduce the corrosion of polishing fluid.

3. High automation, high working efficiency, simple operation, reduce unnecessary manual operation

4. Easy to replace polishing grinding head

5. Easy maintenanc

Mirror polished plates can be applied to

Elevator, kitchen supplies, building supplies, medical equipment, etc.

The advantages

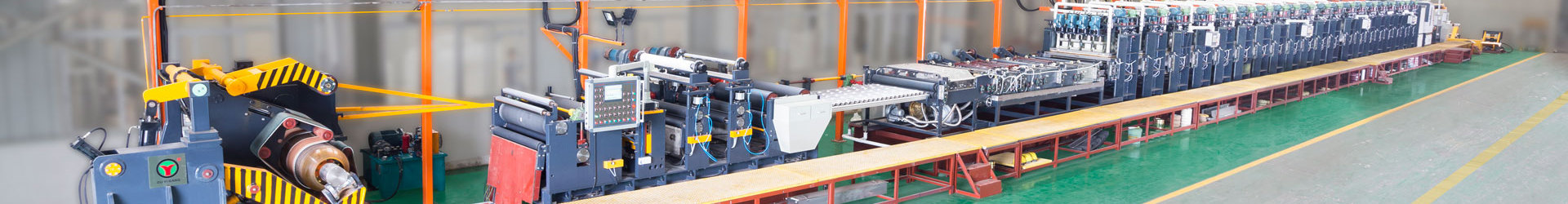

1. The whole line drive motor, grinding head motor, clamping roller and force roller, driving roller and film roller, leveling roller and bottom roller, excessive roller, worm gear reducer, connectors, cardan shaft, bearing seat, clamping roller pressure cylinder, acid water pump, glass bottom plate, multi-pit belt, filter paper, exchange common spare parts to customers to save a lot of costs, purchase time to save a lot of manpower and material resources, Spare parts storage location savings, reduce inventory backlog funds.

2. The synchronization of the whole line is stable, easy to operate, fast in and out of the board, the board head and tail connection control within the range of 600mm effective grinding, efficient key ①, speed up and deceleration restart response speed ②, emergency stop automatic protection of the board surface, the operation and use of personnel are not tired and safe ③ reduce plate waste, higher yield.

3. The whole line covers an area of reasonable design, basic engineering is simple and practical, reduce engineering costs, environmental protection use of waste water to reduce 90% discharge, site layout is convenient for operators to control, safe production.

4. The 8K whole line grinding head layout is reasonable, the pressure is uniform and controllable, save 20%~30% power consumption, greatly improve the grinding speed of 2 ~ 6 meters per minute, match the grinding effect of the board, ensure clear, uniform and bright, reduce energy consumption and cleaning costs, more effective control of the plating color plate, improve the yield.

5. Subsection cleaning machine effectively control cleaning cleaner, cleaning waste water recycling better adjustment, replacement of water is not wasted, can reduce 90% of emissions.

6. The filtration system is clean, energy saving, automatic control, easy to clean, small footprint, acid concentration is easy to adjust, save the best equipment with acid.

7. The equipment has good control, high efficiency, energy saving, environmental protection, excellent value, good cleaning and maintenance, good maintenance, fast replacement parts, strong practicability, high cost performance, is the ideal product for investors.

8. Key advantages processing per square meter of sheet metal saves 0.5 ~ 1.0 yuan of cost compared with other manufacturers, different thickness of the annual processing of about 8000-12,000 tons of output value, saving nearly 600,000 ~ 1.5 million yuan of operating costs annually.

Save the cost of environmental protection of nearly 1 ~ 2 million yuan a year, the equipment is stable, the operation is simple and safe, manufacturing enterprises to find a strong earning ability of the equipment is the truth.