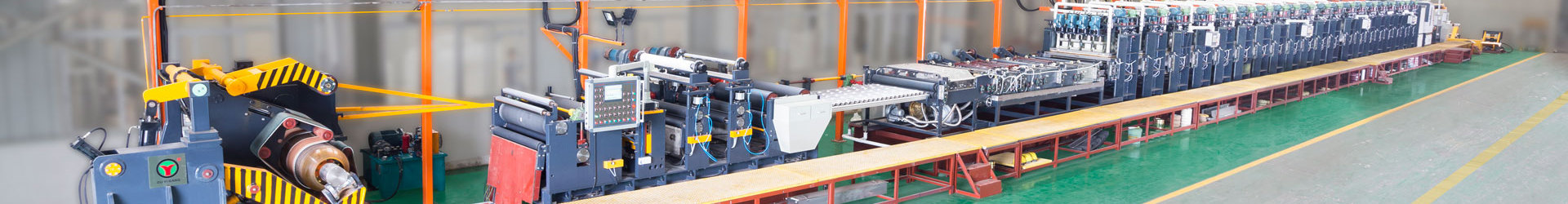

supper mirror polishing machine for Stainless steel sheet

The synchronization of the whole line is stable, the operation is simple, the board input and output are fast, efficient, and the response speed is fast, and the emergency stop automatically protects the board surface.

The area of the whole line is reasonably designed, the basic engineering is simple and practical, the engineering cost is reduced, the site layout is convenient for operators to control, and the production is safe.

High automation, only need two operators, high efficiency.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

Supper mirror polishing machine

for Stainless steel sheet

Appplicalbe stainless steel sheet specification

| Sheet thickness(mm) | 0.6~3.0 | 0.6~3.0 |

| Sheet width(mm) | 1250 max | 1550 max |

| Processing speed (m/min) | 0.5~1.2 | 0.5~1.2 |

| Grade of sheet | 430,439,445,304,316,200 series | 430,439,445,304,316,200 series |

Product Advantage

1. Original and unique design

OUYIGANG Machinery have unique and advanced machine design. It is matching on good material and high-configuration design: Safe, quick, practical and etc that different style for steel processing, welcome to contact us for more information about new design.

2. High & stable quality

OUYIGANG Machinery is from material purchasing, and the whole producing, we guarantee customers “high quality, stable quality”. Our products had passed CE certification, ISO9001-2008, ISO14001 and other quality test report. third part inspection is available whenever it is requested.

3. Well material

OUYIGANG Machinery are produced with well material by high technology, environmental, long service life and safe. It will always create to you a comfortable and reassured work life.

Overall Processing capability

No.4 finish

The basic sheet selection is to be of 2B or BA sheet and should be preferably polished with 150#,180# abrasive belt. The application verticals of this finish to name a few are in cookware, furniture, elevator, architectural decoration, revolving door, exterior decoration etc,.

HAIRLINE finsh

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with 150# 240#abrasive belt. The application verticals of this finish to name a few are in elevator, architecture decoration, revolving door, furniture, home appliance, auto sector, exterior decoration, etc,.

Scotch Brite-Satin finish

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with abrasive wheels or pads. . The application verticals of this finish to name a few are in architecture decoration, elevators and escalators, furniture, etc,.

No.6 finish

These finishes are produced using rotating cloth mops (tampico fibre,muslin or linen) which are loaded with abrasive paste.The finish depends on how fine an a abrasive is used and the uniformity and finish of the original surface. The finish as a non directional texture of varing reflectivity.Satin blend is an example of such a finish.

No.7 finish

This is a buffed finish having a high degree of reflectivity.It is produced by progressively using finer and finer abrasives and finishing with buffing compounds. Some fine scratches may remain from the original starting surface.

No.8 true mirror finish

This is produced in an equivalent manner to a No.7 finish, the final operation being done with extremely fine buffing compounds. The final surface is blemish free with a high degree of image clarity and is the true mirror finish.

Packing&Delivery

Packing type: nacked package, shipped with steel container

Delivery date: 30 days after receiving the deposit

Our Services

After-sale service:We supply life time technique service to our customer and just charge basic cost for comsumable parts.

Contact us

Tel:86-757-88627213

Fax: 86-757-88627213

Mobile phone:+86-13425703089

Address detail :

Factory No.19,Xingliang Road,Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

Province:GuangDong

Country:China