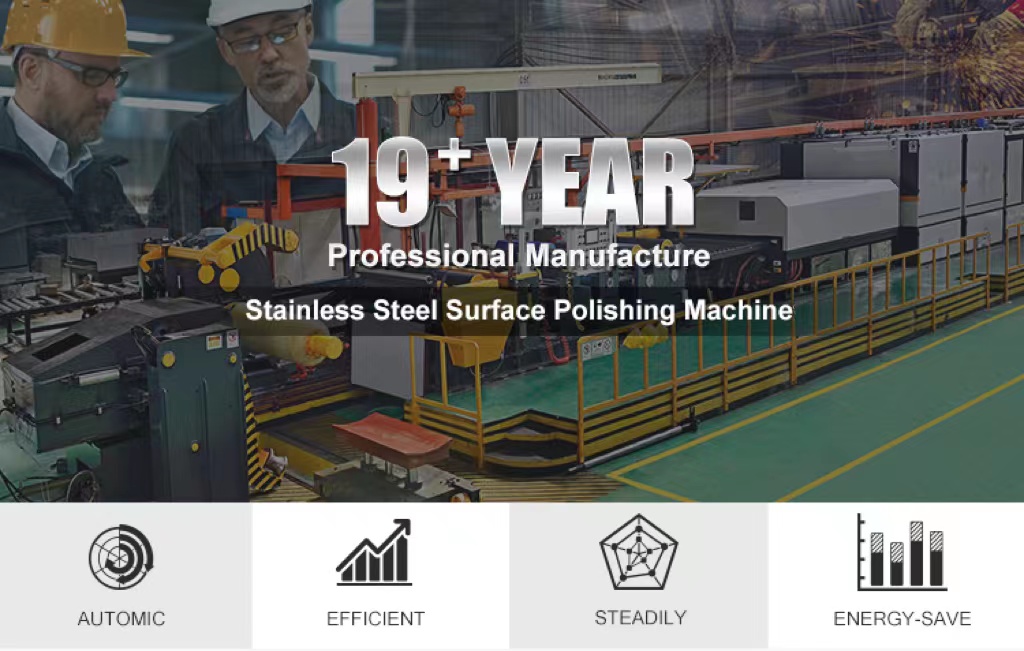

Metal Automatic Polishing Machine Buffing Machine

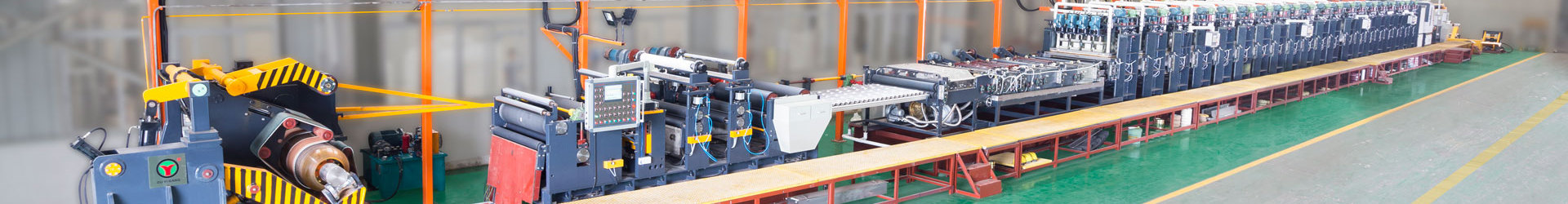

The synchronization of the whole line is stable, the operation is simple, the board input and output are fast, efficient, and the response speed is fast, and the emergency stop automatically protects the board surface.

The area of the whole line is reasonably designed, the basic engineering is simple and practical, the engineering cost is reduced, the site layout is convenient for operators to control, and the production is safe.

High automation, only need two operators, high efficiency.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

Metal Automatic Polishing Machine Buffing Machine

Product Description

Sheet and coil mix in one production line-Finishing style

Hairline finishing for the 2B / BA Plate/ Aluminium/ Alloy/ Steel/ Copper/ Precious metals/ Hardened metals.

It grinds the plate in width is 800-1550 mm, in thickness is 0.3-4.0 mm.

The finishing bright over 358%, the roughness under 0.14 um in hairline buffing.

Advantages: The whole line design concept is unique.

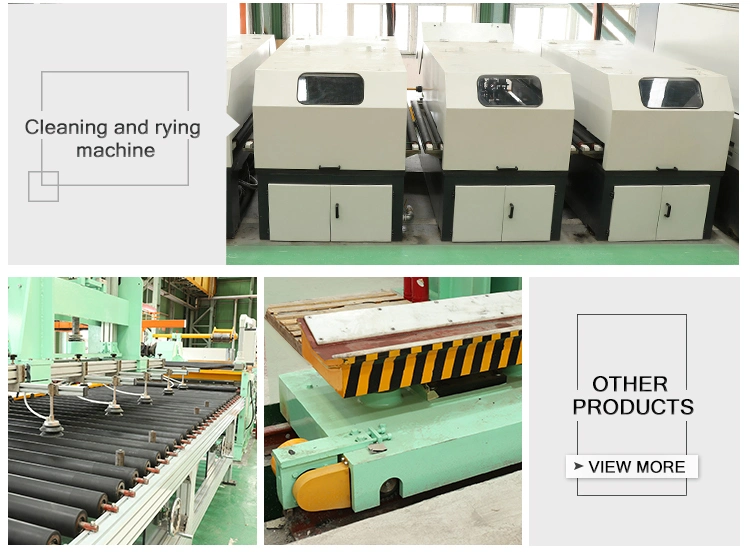

Whole line drive motor, feed roller and force roller, drive roller and film roller, leveling roller and bottom roller, over roller, worm gear reducer, connector, universal shaft, bearing seat, feed roller pressure cylinder, water pump, belt, filter paper, exchange common spare parts to customers to save a large amount of costs, purchase time to save a lot of manpower and material resources, spare parts storage location save, Reduce inventory overhang.

The whole line synchronization is stable, easy to operate, fast in and out of the board, the board head and tail control in the range of 600 ~ 1000mm effective grinding, high efficiency and energy saving, speed up and deceleration response speed, emergency stop automatic protection of the board, the operation and use of personnel are not tired and safe.

The whole line covers an area of reasonable design, basic engineering is simple and practical, reduce engineering costs, environmental protection use of waste water to achieve O discharge, site layout is convenient for operators to control, safe production.

Sander sand belt line speed of 40 meters per second, greatly reduce the cutting oil and sand belt, improve the grinding speed of 40 to 50 meters per minute, matching the grinding effect of the board, to ensure that the sand grain is clear, uniform and bright, good three-dimensional texture, reduce the cutting oil, sand belt and cleaning costs, more effective control of plating color plate, improve the yield.

Hairline machine adopts ring sand belt, cutting fluid spray drawing, better protection of the board surface, thickness and fine sand number matching is selective, quick replacement, improve the board surface sand pattern clear and uniform, to meet customer market demand.

SB polishing machine adopts a diameter of 400 grinding head, improve the grinding effect, increase the frame and rigidity, ensure stability, improve the grinding efficiency, the board does not vibration pattern uniform bright, sand texture is good, to reach the industry leading equipment.

Separate subsection cleaning machine effectively control cleaning cleaner, cleaning waste water recycling better adjustment, replacement of water is not wasted, to achieve O discharge function.

The equipment has good control, high efficiency, energy saving, environmental protection, excellent value, good cleaning and maintenance, good maintenance, fast replacement parts, strong practicability, high cost performance, is the ideal product for investors.

Key advantages of processing per square meter plate compared with other manufacturers to save 0.3 yuan, different thickness of the monthly processing of 3000 ~ 6000 tons of output, save nearly 2 ~ 4 million yuan a year running costs. The equipment is stable, the operation is simple and safe, and the production enterprises find the equipment with strong earning power is the truth.

THE PARAMETERS OF STAINLESS STEEL COIL PRODUCTION LINE

| Plate thickness (mm) | 0.4~3.0 | 0.4~3.0 |

| Plate width (mm) | 1250 | 1550 |

| Speed (m/min) | 6~60 | 6~60 |

| Coil outer diameter (mm) | 1900 | 1900 |

| Coil inner diameter (mm) | 508 (610) | 508 (610) |

| Uncoil bearing (T) | 22 | 25 |

| Length of production line (mm) | 37 | 39 |

| The total power unit (KW) | 465 | 568 |

Contact us

Tel:86-757-88627213

Mobile phone:+86-13425703089

Address detail :No.19,Xingliang Road, Sanzhou Town, Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

City: FoShan

Province:GuangDong

Country:China