Oil Type Grinding Stainless Steel Plate Polishing Machine

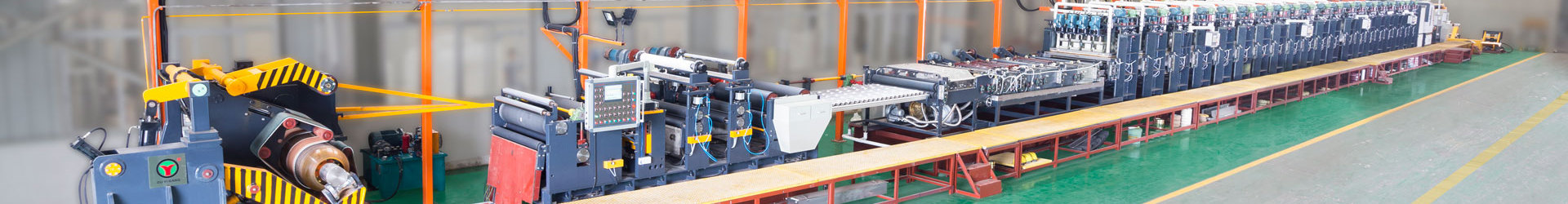

Over the years committed to the research and development of the production of stainless steel CNC sanding machine (No.4), stainless steel polishing machine, stainless steel snowflake drawing machine (HL), stainless steel CNC short grain machine (SB), stainless steel mirror steel machine (8K), grinding machine, grain machine, cleaning machine, CNC lamination machine, winding machine, unwinding machine and other equipment.

Specialized is engaged in the 200, 300 and 400 series stainless steel plate surface treatment and shear distribution services, the company with a number of international leading technology of stainless steel surface treatment production line and intelligent precision machining production line, the surface state satisfy the ultra fine grinding 8 k, No. 4 (snowflake sand), HL (filament), SB (sand smooth) grain of sand and other special custom requirements; To provide customers from the strip, cutting, cutting, plate, laminating, pad paper to distribution and other personalized customized processing center services.

The company's products are mainly used in high-end home appliances, tableware, kitchenware, bathroom, elevator, building decoration, hardware products, precision electronics and various new energy water heaters and many other industries.

The company has excellent production equipment, advanced technology, perfect inspection and considerate service, based on the Pearl River Delta, radiation at home and abroad, to serve the majority of end customers.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

Oil Type Grinding Stainless Steel Plate Polishing Machine

Company Information

FOSHAN OUYIGANG engaged in design and manufacturing the stainless steel surface processing machinery,the factory of OUYIGANG occupies above 20000 square meters, we are the high-tech company of more than 15years production history, which gather science research,design,produce,sale install,adjust and maintenance.

Our company culture: loyalty,dedication, hard-work and cooperation

Company philosophy:Constant cooperation and mutual benefit, to create greater value for our customers.

Our service concept: Your little case is our big events.

The miss of our company: To pursuit perfect quality, then provide professional service.

Company vision: Building one centennial corporation, setting one international brand.

Company core value:

Observe disciplines and obey laws

Conscientious and love in work

Diligent and eager to learn

Cooperation and innovation

Description

The polishing of coils and sheets is one of the most value added operations offered by service centers. Perfect machinery is the key to success in every business, OUYIGANG grinding/ polishing machines are very easy to achieved Matt, Hair -Line, Satin, No.4,No.6 finish. OUYIGANG Metal Surface Polishing Machines can be applied to the top surface of coils and sheets. We are the leading company in the metal processing equipment , our machine cover more than 70% of the Chinese market and is going to meet the worldwide challenge with its extraordinary performance and innovative technology.

Basic specification for the machine

Belt abrasive station | No.4 | / | Hairline |

Brush abrasive station | / | SB | / |

System | Wet roller grinding | Wet roller brushing | Wet roller grinding |

No. of working unit | 2-3 grinding heads | 2-4 polishing heads | 2-3 grinding heads |

Machine weight | Appro 13T | 11T | 13T |

Working width | 900,1250,1500mm, customized available | ||

Sheet size | 1250X2500mm 1550X3000mm customized available | ||

Sheet thickness min / max | 0.3-4mm | 0.3-4mm | 0.3-4mm |

Roller dimensions(Od X width) | 300mm | 350mm | 250mm |

Abrasive belt width | Depending on the sheet width

| ||

Abrasive belt length | 2620mm | 2620mm | |

Speed of the line | 6-25m/min | 6-25m/min | 6-25m/min |

Processing capability:

No.4 finish

The basic sheet selection is to be of 2B or BA sheet and should be preferably polished with 150#,180# abrasive belt. The application verticals of this finish to name a few are in cookware, furniture, elevator, architectural decoration, revolving door, exterior decoration etc,.

Hairline finsh

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with 150#/240# abrasive belt. The application verticals of this finish to name a few are in elevator, architecture decoration, revolving door, furniture, home appliance, auto sector, exterior decoration, etc,.

Scotch Brite-Satin finish

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with abrasive wheels or pads. . The application verticals of this finish to name a few are in architecture decoration, elevators and escalators, furniture, etc,.

No.6 finish

These finishes are produced using rotating cloth mops (tampico fibre,muslin or linen) which are loaded with abrasive paste.The finish depends on how fine an a abrasive is used and the uniformity and finish of the original surface. The finish as a non directional texture of varing reflectivity.Satin blend is an example of such a finish.

No.7 finish

This is a buffed finish having a high degree of reflectivity.It is produced by progressively using finer and finer abrasives and finishing with buffing compounds. Some fine scratches may remain from the original starting surface.

No.8 true mirror finish

This is produced in an equivalent manner to a No.7 finish, the final operation being done with extremely fine buffing compounds. The final surface is blemish free with a high degree of image clarity and is the true mirror finish.

No.9 super mirror finish

Very high degree of reflectivity, brilliant, smooth finish produced by polishing with progressively finer grit abrasives then buffing. Super mirror creates light and space. Best for design, decoration and architecture.

Multi head brushing station, “all in one line ” equipment with No.4—No.6 , Scotch-Brite , Hairline finish

Control by PLC complete with touch screen

Most of the inside construction is made of tempered stainless steel

Horizontal axis rotating and oscillating system

Soft, bright and homogeneous surface appearance

oil and water mixed ,wet type processing

Adjustable brushing pressure

Adjustable brush speed

Easy abrasives brush roller replacement

Adjustable conveyor speed (belt / roller)

Different brush grits combinations are possible to perform different surface treatment

Emergency security switch

Reversal conveyor speed for emergency control

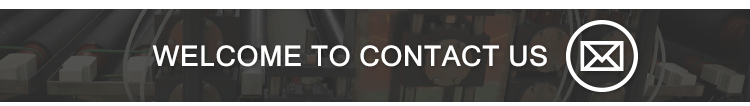

Packaging & Shipping

Packaging: all of the machine, equipment and spare parts spray the rustproof oil, cover with oil paper and plastic film.

Shipping: arrange technical workers to load the machine with crane , fixed the machine to the container with strong steel rope, and guarantee your machine shipped to your port without any human causing damage.

After-sale Services

We supply life time technique service to our customer and just charge basic cost for comsumable parts.

Contact us

Tel: 86-757-88627213

Mobile phone: +86-13425703089

Address detail: No.19,Xingliang Road, Sanzhou Town, Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

FAQ

Q1. How to get the most suitable polishing machine and best price

A: Please tell the material you want to working on? and the specification of your working material?

Q2. Do you have the manual of the polishing machine Except the automatic machinery?

A: Yes, we have.

Q3. If we don’t know how to use the polishing machine, can you teach us?

A: our customer support engineer will go to cutomer's factory to install the machine , and they will teach the skilled labor complete knowledge about the machine.

Q4. Do you have the machinery applying to the special steel sheet?

A: When the sheet thinckness comes to 4mm and more then 4mm, or there is some special performance to your sheet,it is suggested that the customer come to our company talk about the technical requirement with our engineers.

Q5. What is the useful life of your machine?

A: The useful life of the equipment depend mainly on the maintainability, and our machine can be used for more then 6 years ,most of it come to above 10 years under normal operation and maintenance.